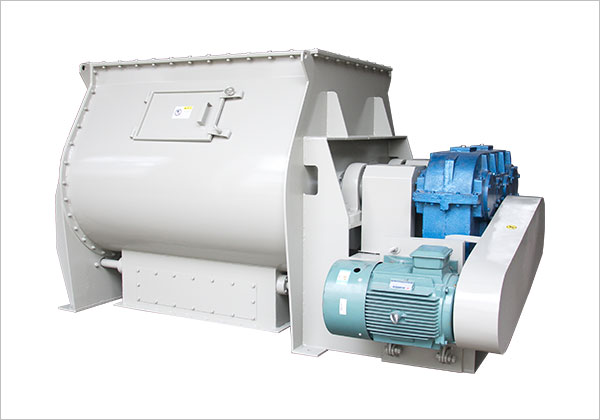

Double Shafts Paddle Mixer

Introduction

Double Shafts Paddle Mixer is of a low energy consumption and a large loading coefficient, moves steadily, is in sealed operation, without pollution to the environment, and easily used, maintained and repaired. SYJW dual-axis paddle horizontal mixer (also called as: gravity-free grains mixer or dual-axis paddle mixer) is broadly applied for the material mixing process in chemical, agricultural chemicals, pharmacy, dyestuff, beverage, food additive etc. industries, including solid-solid (powder to powder) and solid-liquid (liquid sprayed powder) mixings and the mixing and drying operations under a vacuum state. The mixer features quick mixing,high mixing precision, non-produced segregation, warm mixing process, low energy consumption, large filling coefficient, steady movement, sealed operation, non-environment pollution, easy installation, use and repair.

Working principle:

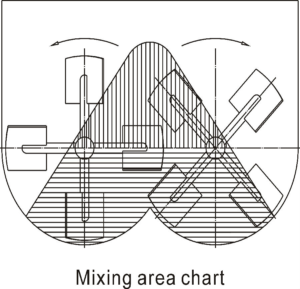

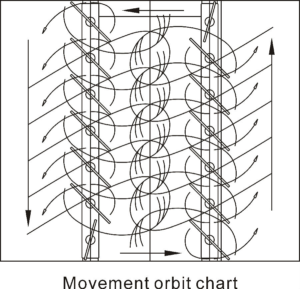

Driven by the directly-connected decelerator,the chains drive the dual-axis rotor to move reversely at a certain speed and, during the movement, the paddle on the axis makes the material go ahead on the one hand and, on the other hand, throws it along with the radial direction to the oblique-front space. The materials on the two sides move in the reversed areas of their own to go to and fro to get direction and are mutually dissolved into the penetrated and mixed so that a fluidized weightless area and rotating vortex is formed in the central part and continually moves along with the axial and radial directions so as to form a full-respect combined cycle to quickly get the uniform mixing effect.

Product introduction

1.Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination between the part contact with the raw material and the parts don’t contact with the raw material.

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

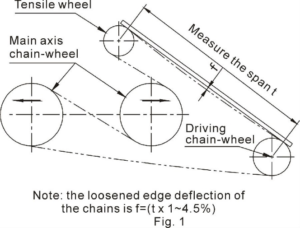

2.Reliable driven unit

The driven unit, power and speed are varied according to different raw material, starting method, and processing.Because of the meshing relationship for the paddles, the double shaft driven unit is required to be equipped with synchronous ability. The four different driven combination launched by Gangye Co. can meet different requirements of two synchronous gear box, double output gear box, double synchronous planetary gear box, and the combination of reducer and chain.The combination of Sk-series double synchronous gear box is the best configuration for double shaft paddle mixer.

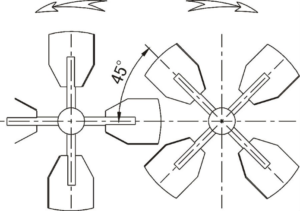

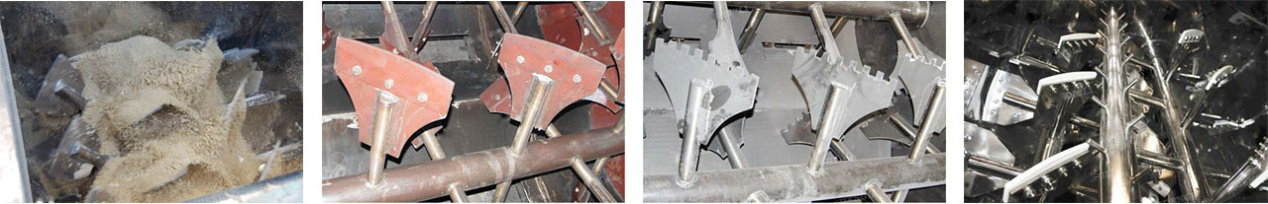

3.High efficiency mixing unit

According to the properties of raw materials, the paddle can be adjusted and designed accordingly, for example adding wear-proof plate, Teflon plate, and saw-toothed paddle.

Double shaft paddle mixer can be also added high speed breaking bar inside the barrel, scattering material following its flow.

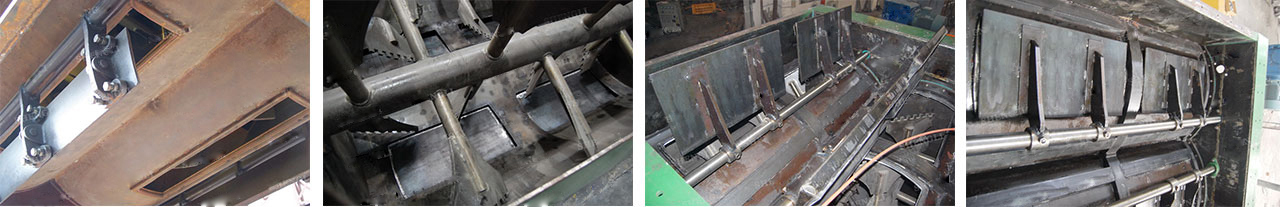

4.Excellent discharging unit

Standard valve for double shaft paddle mixer is twin pneumatic planar flap valves. When close the valve, the planar flaps match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

Specification

Standard Features:

- Volume: 500-10000L

- Stainless Steel or Carbon Steel

- Ribbon agitator for center discharge

- Designed for normal temperature and normal atmospheric pressure

- Feed Nozzle

- Dust Nozzle

- Manually operated or Pneumatic operated flap valve

- Packing Seal

- Safety limit switch on man hole

Optional Features:

- Carbon Steel, Stainless Steel 304, Stainless Steel 316L

- Sanitary type construction Flap valve, bomb-bay door

- Horsepower to suit higher density materials

- Explosion-proof motors

- Controls such as variable frequency drives, motor starters and operator stations are available

- Spray nozzles for liquid introduction

- High Speed chopper

|

Model |

VZH |

|||||||||

|

Norm(m³) |

0.3 |

0.5 |

1 |

2 |

3 |

4 |

6 |

8 |

10 |

|

|

Loading coefficient |

0.4-0.6 |

|||||||||

|

Power of motor (kw) |

4 |

5.5-7.5 |

11-15 |

18.5- 22 |

22-30 |

30-37 |

37-45 |

45-55 |

55-75 |

|

|

Speed of main axis (r/min) |

78 |

51 |

51 |

51 |

36 |

36 |

36 |

29 |

29 |

|

|

Size of feed port (mm) |

Φ400 |

Φ500 |

Φ500 |

Φ500 |

Φ500 |

Φ500 |

Φ500 |

Φ500 |

Φ500 |

|

|

|

|

|

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

Φ350 |

|

|

Size of discharge port(mm) |

350*40 |

500*90 |

500*90 |

500*90 |

500*90 |

500*90 |

500* 90 |

800* 200 |

800* 200 |

|

|

Out-form dimensions(mm) |

L |

1242 |

1408 |

1875 |

2275 |

2408 |

2822 |

3050 |

3362 |

3538 |

|

|

M |

1278 |

1478 |

1692 |

2108 |

2396 |

2546 |

2980 |

3412 |

3645 |

|

|

H |

1025 |

1305 |

1425 |

1775 |

1955 |

2015 |

2235 |

2425 |

2615 |

|

Equipment weight(kg) |

750 |

1000 |

1550 |

2500 |

2900 |

3600 |

5600 |

7100 |

8000 |

|

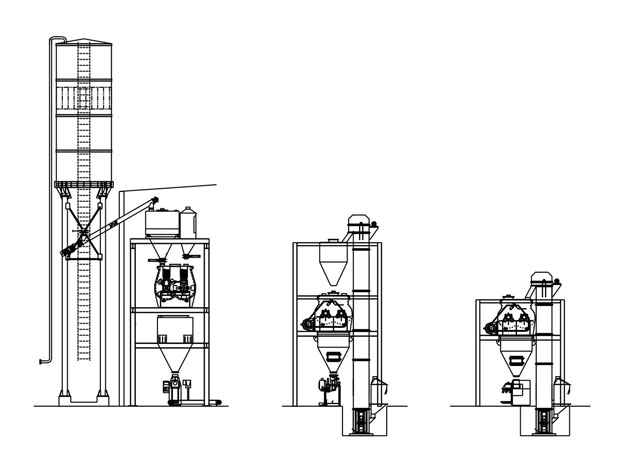

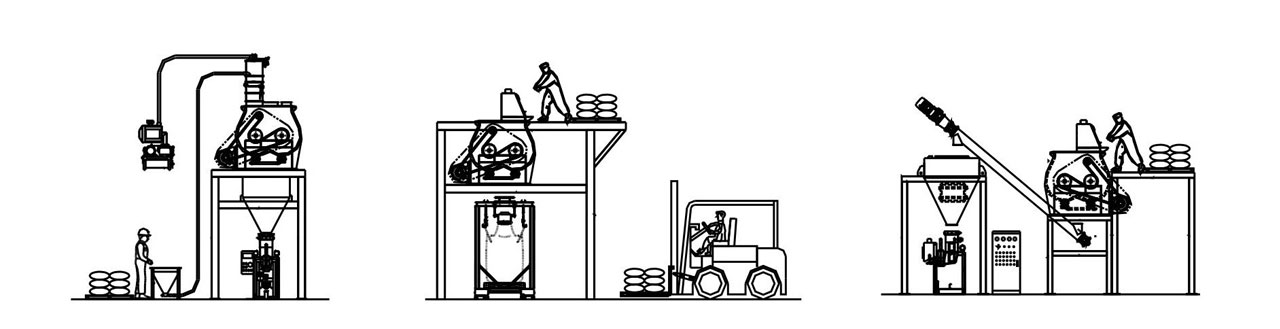

Accessory project

Placing in the production line, and combined with raw material silo, dosing system, conveying system, production silo, and packer, the non-gravity mixer can achieve the scale production. All equipments in the production line should be placed and coordinate with each other reasonably to realize the most efficient production.

Configuration 1: vacuum feeder, production silo under the mixer, and packer under silo

Configuration 2: manually feed with the folk lift, bulk-bag packer under the mixer.

Configuration 3: manually feed, discharged to conveyed to production silo, then packing.

Download

Matching parts

A、Mixing Effect

Despite the materials are different in proportion and diameter, it can achieve a good mix effect under the quick and fierce seethe and cast of staggered agitating blades.

B、Crash Device

Crushing device is needed when the material agglomerating. “Crushing Stick” with triangle tooth enclosure maintains high rotating speed of over 1400rpm, which smashes and depolymerizes the agglomerating materials in the material weightlessness area.

C、Discharging Mode

The materials are usually discharged by pneumatic (manual) flap valve. The arc valve can be embedded tightly into the cylinder and be parallelized with inside cylinder wall without material deposit and mixing dead angle. The standard product can be classified into small door and large door that opens to the side of cylinder, delivering clean and quick material charging and little residue.

D、Double Layer Blade

To decrease the replacement costs of easily damaged parts, the paddle blade can be shaped as 2-blade type, on whose base underlaid a movable little blade which can be changed directly, economically and quickly.

E、The Gap Between Blade and Cylinder

The gap between paddle blade and cylinder wall directly affects the mix result and the material residue within the mixer after discharging materials; the gap of our products is in range of 3 to 5mm.

F、20 Cubic Meters Total Volume

This series mixer can conduct complete volume of 203 m at the most. It is significantly different from the general specification in terms of transmission form of large scale device and the base of mixer.